Industry News

How will the Popularization of DC Distribution Networks Disrupt the Traditional Reactive Power Compensation Architecture?

In addition to the technical specifications, configurations, etc., analysis of direct current power distribution, no success in the design, and the new structure provided by the current industry model for reference.

29 2025-09

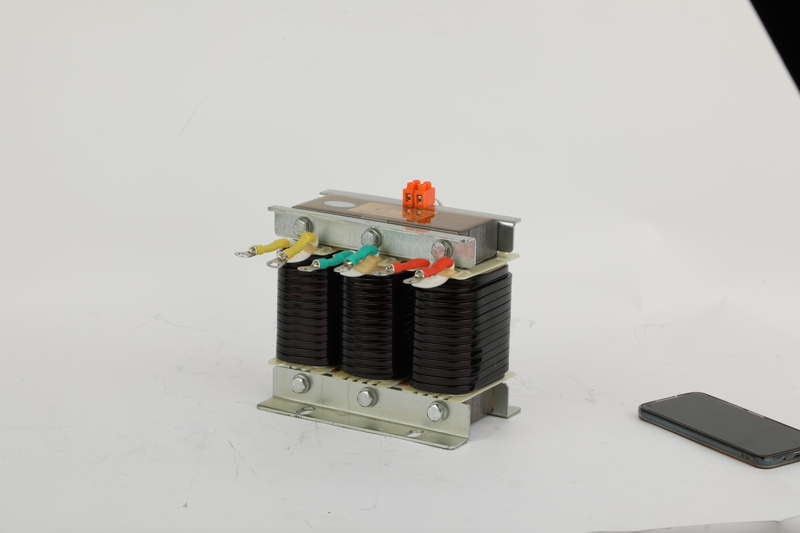

29 2025-09 How Does The Next-generation Series Reactor Achieve Breakthroughs In Energy Efficiency And Space Reduction?

This article describes a new generation of flat coil series electrical appliances, with innovative structure and materials to achieve energy efficiency increase, volume reduction, adapt to various scenarios, and provide optimization solutions for green energy systems.

How Can the Response Speed of Dynamic Compensation Devices Be Further Enhanced through Semiconductor Technology, Such as IGBT?

In modern power systems, the significance of power quality is becoming increasingly prominent. As a crucial equipment for ensuring the stability and efficient operation of the power grid, dynamic reactive power compensation devices play an indispensable role. Our company, Geyue Electric, as a manufacturer specializing in the research and development of low-voltage reactive power compensation equipment, has always been committed to improving product performance to meet the increasingly stringent requirements for power quality in the industrial sector.

25 2025-09

25 2025-09 How does the Industrial Metaverse Provide New Debugging Tools for Reactive Power Compensation Systems?

Geyue Electric uses virtual commissioning, AR, remote collaboration and digital twins to explain how the industrial metaverse helps reactive power compensation systems reduce risks and improve efficiency, and promotes digital upgrades in power.

24 2025-09

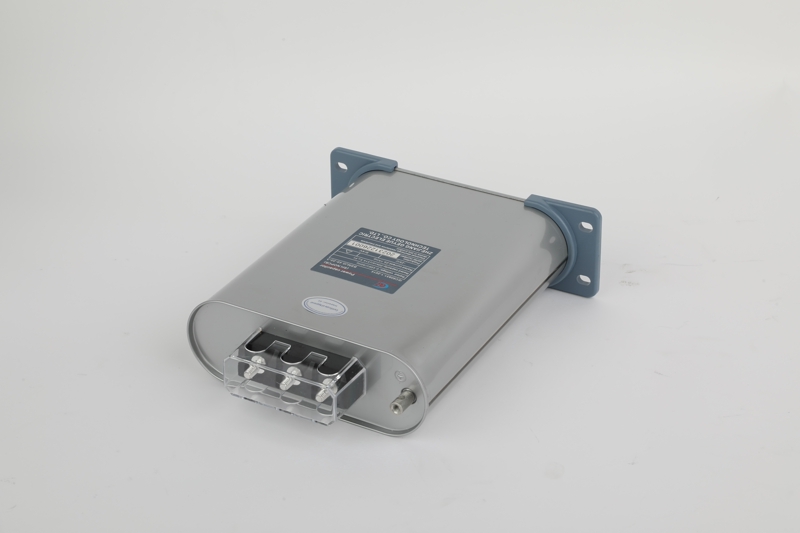

24 2025-09 Why do Power Capacitors Keep Short-Circuiting? A Must-Read Guide for Electricians Troubleshooting Common Compensation Cabinet Faults.

This article analyzes the causes of power capacitor failures such as bulging and oil leakage, provides troubleshooting methods and preventive measures, and offers a practical guide for electricians to solve common problems in compensation cabinets.

23 2025-09

23 2025-09 How Can the Problem of Excessive Capacitive Reactive Power in New Energy Power Stations Be Effectively Solved?

Geyue Electric proposes intelligent optimization and other solutions from three aspects: the nature of the problem, technical paths, and innovative solutions, to help new energy power stations solve the pain point of excess capacitive reactive power.